We are one of the world’s leading companies in liquid transfer services and portable pumps equipment.

At Gulf Offshore NS LTD, we are experts when it comes to liquid cargo and portable pumps. Over the years, we have provided the safe and reliable transfer of:

- Bunker fuels

- Edible oils

- Vegetable oils and used vegetable oils (Including UCO flexi-tank handling)

- Biofuels & Oleochemicals

- Oil & Petrochemicals (Including inerting of holding tanks)

- Liquefied Natural Gas & Liquefied Petroleum Gas

- Chemicals

- Lube Oils

- Cargo with high viscosity and/or pour point (Including (re)heating)

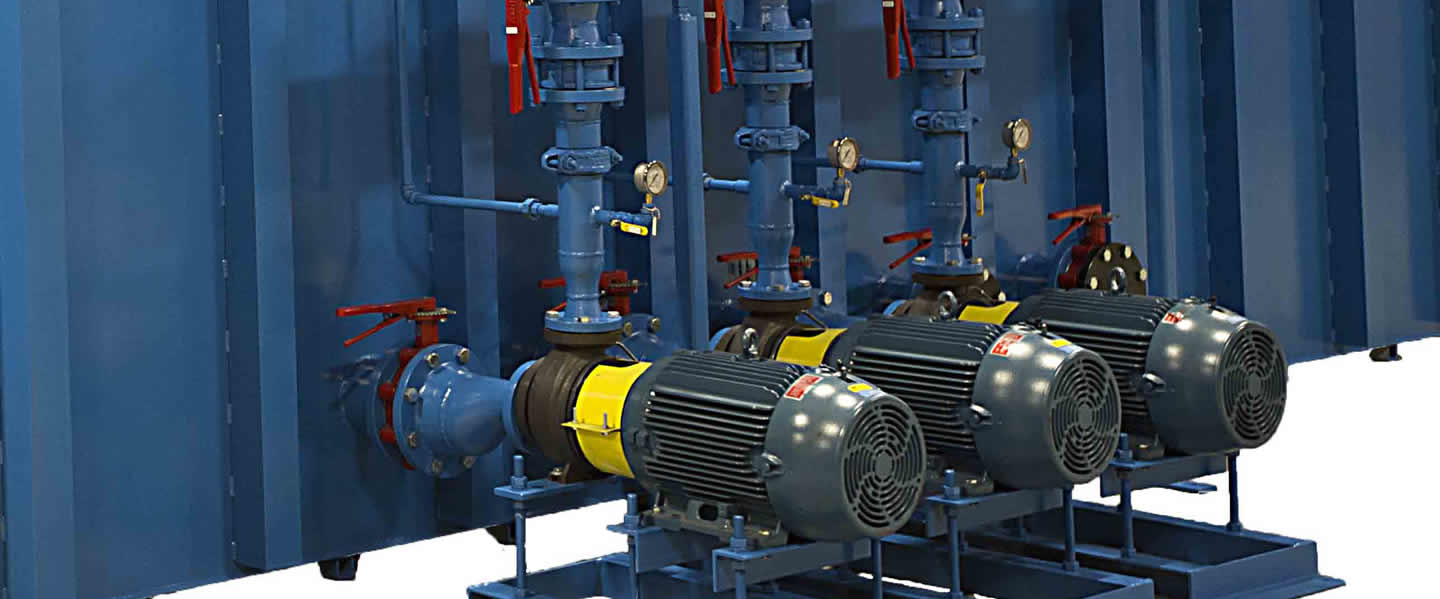

All our liquid transfer services are conducted using Liquid pumps. These hydraulically powered, lightweight pumps are built to deliver high-capacity flow and pressure, making them perfect for use in challenging operations across a wide range of industries.

Whether you need help handling your cargo, fuel or ballast water on board your vessels or, are looking to transfer industrial and petrochemical liquids onshore, Liquid has you covered.

Gulf Offshore NS LTD performs successful offloading with hydraulically powered pumps

Challenge

A chemical tanker was loaded with styrene monomer for shipment. However, an incorrect inhibitor caused the cargo to polymerise and reach a viscosity of close to 100,000 cSt, making it extremely difficult to pump out using standard pumping solutions. In order to complete the shipment, the owner needed a way to offload the cargo.

Solution

To tackle the problem, our team explored different ways of offloading the cargo, taking into consideration the viscosity as well as the chemical properties of the styrene monomer. We also discussed the type of pump to be used and the flow rate needed. After much deliberation, we came up with a one-of-a-kind, innovative pumping solution that would enable us to achieve an optimal flow rate. Using an intrinsically safe Gulf Offshore NS LTD diesel hydraulic powerpack to drive the pumps, we successfully discharged 150 metric tonnes of polymerised styrene monomer with a viscosity of 90,000 cSt at a steady flow rate.

Result

With the help of our team, the cargo was successfully offloaded and delivered. The speed of the operation also enabled us to deliver time and cost savings to the client.

Other notable projects

- Reheating of more than 50 containers with solidified used cooking oil and subsequent transfer to an inland barge at our own jetty in the port of Rotterdam.

- Discharging of at least 100,000 metric tonnes of molasses per year worldwide using the lightweight Pro Liquid High Viscosity Pump.

- Discharging of 35,000 metric tonnes of condensate slobs from an FPSO that caught fire in Brazilian waters. After the vessel was towed to Singapore for repairs, Pro Liquid successfully executed the inerting, discharging and de-ballasting of the vessel in Karimun, Indonesia before it entered the shipyard.

- Project management of loading and subsequent discharging of 40 metric tonnes of MEG from ISO tanks onshore onto an offshore vessel.

- Continuous dewatering and desludging of several water-oil separation pits for an oil refinery in Brunei using various types of Pro Liquid pumps.